General Information

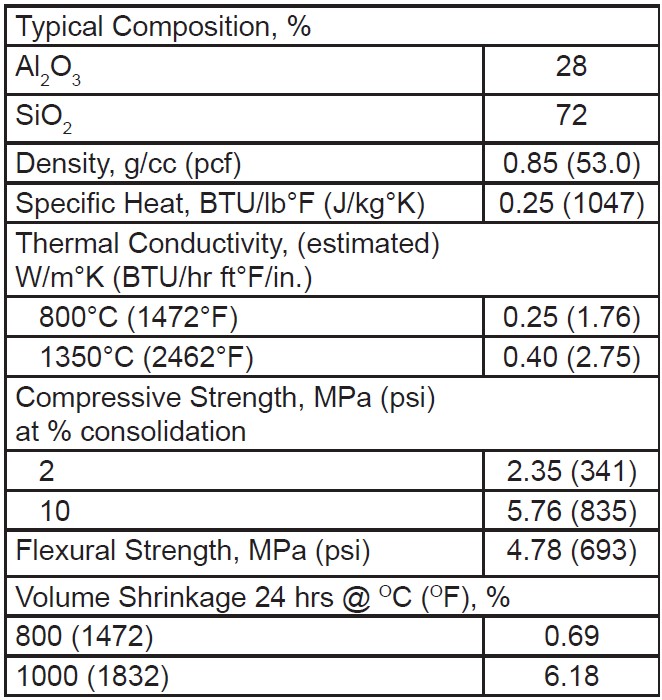

ZIRCAR Ceramics’ RNKO-HD Alumina-Silica board is a uniquely strong, low-density combination of 1260oC rated Al2O3-SiO2 (RCF) fibers and a stabilized inorganic amorphous SiO2 binder.

RNKO-HD is 100% organic free. At 0.85 g/cc (53 pcf) density, RNKO-HD has been developed for applications where a combination of low thermal conductivity and the abilty to withstand high compressive loads at high temperatures are required.

RNKO-HD exhibits excellent resistance to chemical attack and is not affected by oil or water. It is, however, affected by hydrofluoric acid, phosphoric acid and strong alkalis.

Characteristics & Properties

The data presented herein is intended to help the user determine the appropriateness of this material for their application. This data is a nominal representation of this product’s properties and characteristics and therefore should not be used in preparing specifications.

RNKO-HD – strong enough for your application?

This is a good question. Simulating your exact application conditions, in a laboratory setting, is extremely difficult to do. Presenting data in a way that conveys useful information about how a product will perform in your application can be a real challenge. As an example, does data that states the temperature at and the load under which a product is completely crushed mean anything in an anisotropic condition with hot refractory or molten non-ferrous metal on one side and a water cooled shell on the other?

ZIRCAR Ceramics has always believed the “proof is in the pudding.”

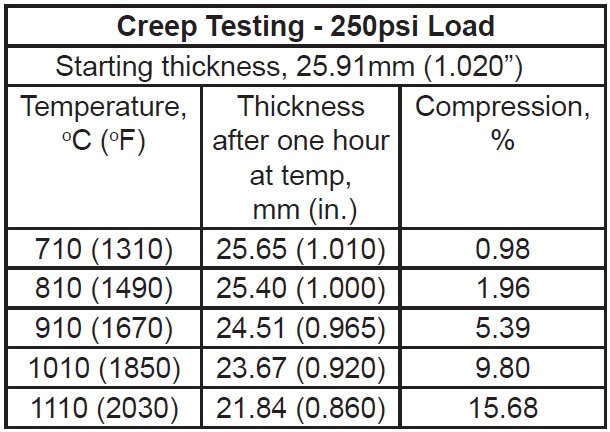

In addition to the compressive and flexural strength data presented on page 1, ZCI developed a Creep Testing Apparatus designed to present a very clear set of data – a set of data that shows percent compression after one hour at a range of temperatures. The table below presents the data.

The data presented herein is intended to help the user to determine the appropriateness of this material for their application. This data is a nominal representation of this product’s properties and characteristics and therefore should not be used in preparing specifications.

Suggested Applications

Foundry: Refractory backup insulation in equipment used to transport molten metal – Ladles, Tundishes, Troughs, Crucibles, Torpedo Cars.

Secondary Aluminum: Molten metal contact applications – troughs, headboxes, launders, floats, nozzles, dams and many more.

Glass: Refractory backup insulation in molten glass equipment – expected to provide decades of uninterupted service.

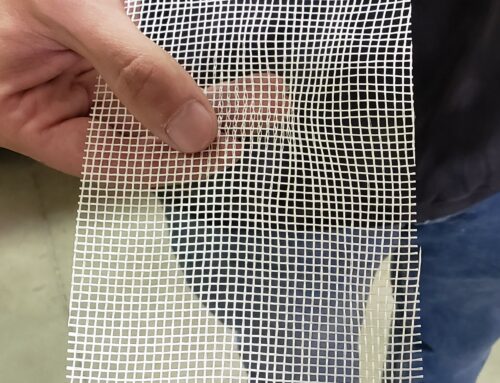

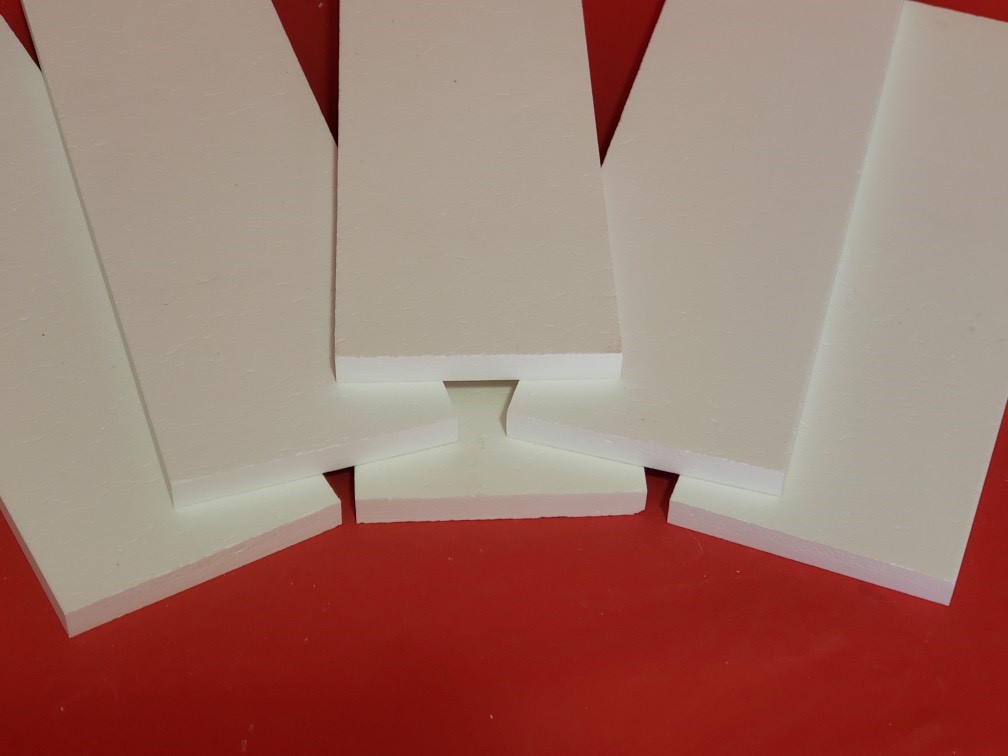

RNKO-HD is highly machinable with the use of conventional dry carbide tooling.

Large format is ideal for use as feedstock for precision machined components.

RNKO-HD is produced in flat sheets up to 16” x 96” x 1”.

Pictured above is ZIRCAR Ceramics’ Creep Testing Apparatus wherein a 250psi load is applied to a 1” cube sample. Data was collected after one hour at 710oC, 810oC, 910oC, 1010oC, and 1110oC.